The Ultimate Guide To The CO² Hemp Extraction Method

CBD For Seniors: Understand The Benefits & How It Works

April 4, 2020

CBD for Athletes – How CBD Can Boost Performance and Recovery

April 24, 2020There are several ways to extract CBD from hemp. From carrier oils to solvents, all have pros and cons. But the ideal extract method for Hemp CBD is with supercritical CO2 process because it’s the safest and most accurate method. Below are the essential details about how processers remove CBD and the other important compounds from the hemp plant.

CO² Hemp Extraction for CBD: From the Farm to the Factory

When you receive your hemp extract CBD products, they’re in a usable form. The oil absorbs into your bloodstream under your tongue. Edibles are ready to pop into your mouth and go through digestion. The jar of salve gets opened and slathered on sore muscles.

To get to this point, hemp farmers carefully harvest their crops. Then the plants must dry adequately before the extraction process can start. While there are systems pending patent, that can extract the compounds from freshly harvested plants, that’s not an option at this time for most brands. As this option becomes more readily available, it will be a better choice for reducing mold, which can grow when plants don’t dry right.

When curing hemp, it needs circulating air. Too much circulation and movement can cause the terpenes to dissipate. Farmers and producers need to be extremely careful during this process to preserve the compounds and prevent mold before moving to the removal process.

What is CO² Hemp Extraction for CBD?

There’s nothing new about CO² hemp extraction. Before CBD, it was used for legal, medical cannabis products and probably more widely used, various essential oils. To separate the compounds from the plant matter, you need a solvent. Most liquid solvents, such as ethanol, destroys the terpenes and can leave behind small amounts in the oil, which is extremely dangerous.

With supercritical CO² extraction, you’re using carbon dioxide as a solvent, and it remains a gas, leaving behind zero residual matter. Additionally, producers use a closed-loop extraction system to improve safety during the process. With solvent-based options, lab accidents are possible due to the volatile nature of the chemicals.

It’s actually a two-step process. The high-pressure supercritical extraction strips the plant matter bare, taking everything, including waxes, lipids, and fats. You want to keep the cannabinoids, terpenes, fatty acids, minerals, and vitamins. But the waxes, lipids, and fats need to go.

To do this, you use a winterization process that uses 200-proof alcohol to strip them out through lots of stirring. Next, it’s put into a deep freeze for eight to twelve hours. This part helps separate the different elements, and the mixture goes through a filtration system. The remaining oil is heated, and the alcohol burns off. Alcohol burns at a lower boiling point than the oil, removing all traces before you get to the final product.

Why is CO² Extraction the Best Method for Extracting CBD?

As mentioned at the beginning, there are multiple methods for separating CBD from the hemp plant. Each method has pros and cons, but the truth is that CO2 extraction is the best method for removing CBD. Using a carrier oil, such as olive or coconut oil is ideal for individual batches, but not for large-scale production. Solvents, including high-grade alcohol, is dangerous for the lab that does the work and doesn’t produce a safe product.

One business owner explains his decision to use supercritical CO2 extraction,

“Unlike alcohol or butane, CO² is a highly tunable solvent, meaning you can pull unique compounds from botanicals at different pressures and temperatures. This opens the door for a ton of creativity in the extraction process, which was attractive to us. CO² is also safer than many hydrocarbon techniques which use flammable and toxic solvents like butane.”

He goes on to explain the importance of the method aligns with the different techniques for using plant-based products, which includes vaping. While toxic solvents are a problem in any item you’ll ingest, heating the oils at high temperatures and inhaling the vapors into your lungs can be very dangerous with non-vetted products.

Is CO² Hemp Extraction for CBD Process Different for Broad Spectrum?

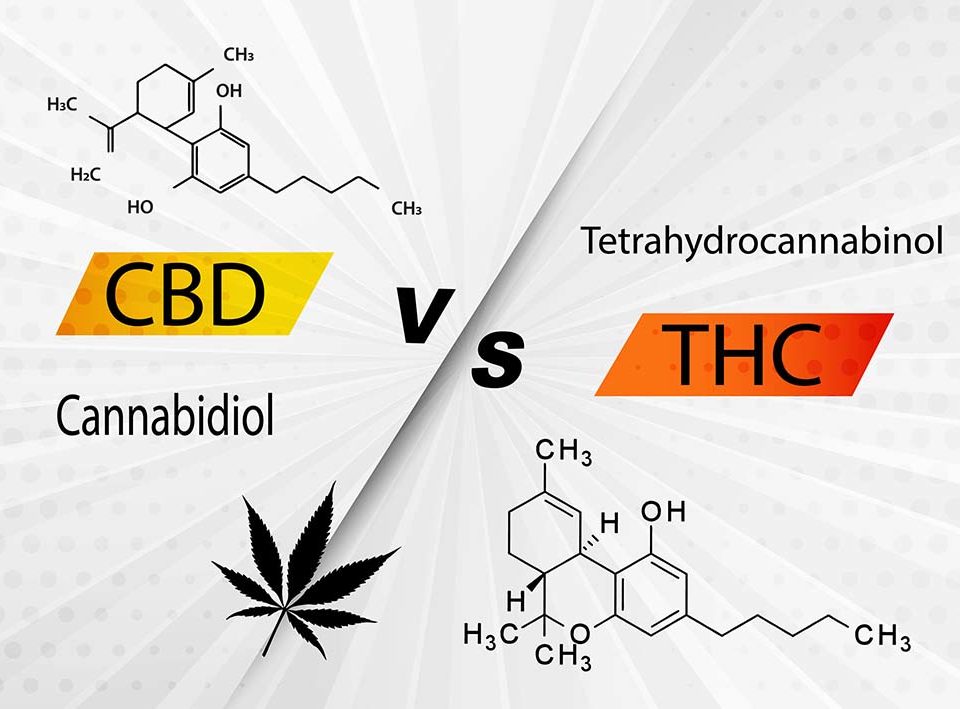

The only part of the extraction process for broad spectrum CBD oil that’s different is the final steps. The broad spectrum goes through a full distillation procedure to get you a 99.99% pure CBD isolate, which is similar to going through the entire winterization process a second time to separate each compound. However, rather than tossing those cannabinoids and terpenes and leaving just a crystalline substance, producers add-back all the vital compounds except for the THC. Removing only the THC is possible because each chemical has a separate boiling point.

The process leaves you with the full spectrum of hemp’s benefits, but without the THC. While many people are okay with the psychoactive compound in their CBD products, it can show up on a drug screening and can increase anxiety in many consumers.

Yes, this may sound complicated, and it is if you’re not a professional. CO2 hemp extraction for hemp CBD should only be done by professionals with the right equipment that understands and abides by all safety steps and procedures. Brands should also send samples from all batches to a third-party lab for independent testing. Our Certificate of Analysis is your proof that our products have undergone rigorous testing and only contain natural ingredients.